Home ▸ Products ▸ Feedout Equipment ▸ BvL Feed Mixer Wagons ▸ BvL Feed Mixer Wagons

BvL Feed Mixer Wagons

BvL

BvL Feed Mixer Wagons

BVL Mixer Wagons range from 6.5m3 to 46m3

“Increase Productivity – Drive Profitability”

It is not just BvL’s 150 years of experience in the construction of agricultural machinery that has its reputation, it is also the German determination to succeed in products of reliability & quality. As a result of this focus, BvL’s family-owned company continue to become world leaders in innovative ideas, fully developed technology and comprehensive service.

Faster and easier mixing process for high fodder quality

Exact fodder discharge with the patented EDS system

More than 1000 variants: The right machine for every farm.

Highest quality, Made in Germany,

Reliable, sturdy and innovative technology

The patented EDS (Exact Dosing System) provides a fast and consistent discharge. With the asymmetrically arranged side doors, the fodder comes out at the widest point on the side of the mixer wagon, deposited in a loose even swath without driving over it.

Fast, with optimal volume utilization

The asymmetrically positioned counter knives guarantee an optimal interface between the two mixing chambers. With the optimised geometry of the counter knives, the BvL achieves excellent volume utilisation with a relatively low power requirement.

High degree of mixing

High volume utilisation

Low power requirement

Specifications

| Model | V-Mix 8-1S Plus | V-Mix 11-1S Plus | V-Mix 15N-2S Plus | V-Mix 17N-2S Plus | V-Mix 20H-2S Plus | V-Mix 24H-2S Plus | V-Mix 27-2S Plus | V-Mix 34-3S Plus | V-Mix 40-3S Plus | V-Mix 46-3S Plus |

|---|---|---|---|---|---|---|---|---|---|---|

| Capacity | 8m3 | 11m3 | 15m3 | 17m3 | 20m3 | 24m3 | 27m3 | 34m3 | 40m3 | 46m3 |

| Width with one side door | 2130mm | 2390mm | 2355mm | 2355mm | 2355mm | 2355mm | 2470mm | 2355mm | 2470mm | 2530mm |

| Width of Mixing Hopper | 2050mm | 2270mm | 2270mm | 2270mm | 2270mm | 2270mm | 2370mm | 2270mm | 2370mm | 2470mm |

| Overall length | 4800mm | 4930mm | 6820mm | 6860mm | 6930mm | 6945mm | 7650mm | 9335mm | 9850mm | 10215mm |

| Height | 2620mm | 2975mm | 2450mm | 2600mm | 2850mm | 3150mm | 3200mm | 3150mm | 3350mm | 3755mm |

| Empty Weight | 2950kg | 4100kg | 6050kg | 6380kg | 6600kg | 7000kg | 8410kg | 11300kg | 12200kg | 14000kg |

| Max Payload | 3360kg | 4620kg | 6300kg | 7140kg | 8400kg | 9830kg | 10090kg | 14280kg | 14300kg | 19000kg |

Features & Benefits

BvL Construction

BvL’s are constructed with a 20mm floor plate and 8mm sidewalls. The sidewalls are lapped at the joints and fillet welded on both sides. This double thickness is positioned at the highest wear point of the bowl – greatly increasing the wall strength and life expectancy.

Auger flight joins are normally a weak point on mixer wagons. BvL overcomes this by overlapping each join resulting in unmatched strength and durability.

The anti-spill ring works by preventing feed spillage out of the wagon while mixing – especially effective on dry & fibrous material. The anti-spill ring holds pressure on the material for the augers to cut & mix faster with maximum consistency. It also increases the strength of the bin in the event of the loading tractor hitting the mixer.

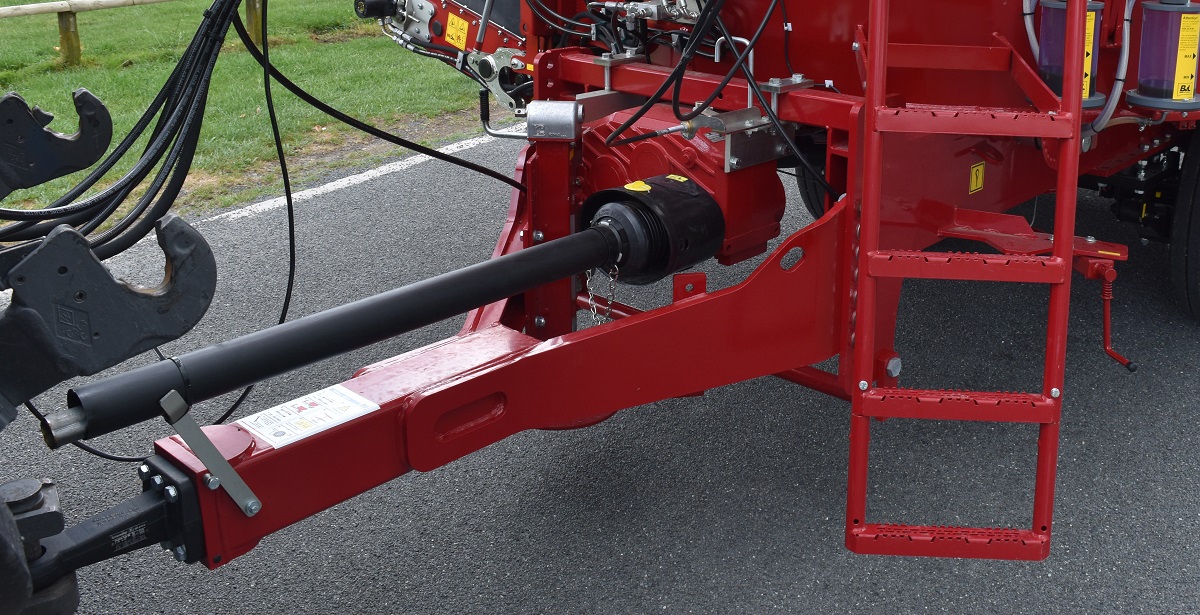

BvL Mixer Wagon Chassis

The BvL is running on a separate truck-style chassis, designed to take out the ex and vibration of driving around the farm. There are four independent weigh cells, one in each corner for consistent weighing. (Versus many other mixers which have the chassis welded to the mixing bowl with only 3 weigh cells. One on each axle and one on the drawbar. This system gives a less accurate weighing.)

BvL Exact Dosing System

This system uses the asymmetrical design along with the sharks bite on the augers to ensure full utilization of the bowl capacity and to make sure that trace elements which find their way to the bottom of the bowl are evenly mixed. This, in turn, results in a consistent ow of product discharged through the door opening that is positioned at the widest possible position to ensure the product is deposited as a loose, even swathe.

BvL heavy Duty Elevator

The specially designed ‘V’ shaped self-tracking & self-cleaning cage rollers are at the heart of the BvL conveyor system, eliminating build-up and keeping tracking true. Quality is further enhanced with a 6mm double layered rubber belt. The centring guides and cleats are made from tough vulcanised rubber, and the belts are set with a very simple yet strong joiner that ensures a long and trouble-free life